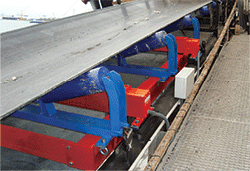

Conveyor belts

are a ubiquitous feature in most industrial facilities and for many good

reasons. Since the invention by Richard Sutcliffe in the early 1900s, these systems have continued

improving efficiency in factories by enabling automation of material movement.

They also help in space maximization while also reducing your labor and energy

costs.

One of the features that helps optimize these

systems is a conveyor belt scale. These help to

measure the material load as it travels over the belt. This is possible because

as material moves down a conveyor belt it exerts a force proportional to the

material load.

However, the fact that the scale is out of

sight leads to neglect which in turn affects its accuracy of capabilities. Like any other system involved in handling

materials the need for maintenance cannot be gainsaid. When

bulky materials are involved the problem is exacerbated thus calling for

regular checkups and proper maintenance to avoid inaccurate measurement.

An ideal scale will provide weight results

that tally with those provided by National Institute of Standards and

Technology (NIST)’s Handbook. While most products in the market offer accuracy

guarantee it is important to note that simple maintenance ensures the

capability of the scale is not compromised.

As a facility owner, you need to understand

the main installation and maintenance guidelines in order to care for the belt

scale as per required standards.

Main Installation Tips

According to industry experts most scales are

affected by poor installation. Lest you fall into this pitfall consider some of

these tips to get the most out of your scales:

Correct Positioning

This is one of the greatest factors which

determine the functionality of the scale. You must ensure the scale is

positioned where there is minimal tension and consistence. The best position

according to National Type Evaluation Program

(NTEP) is close to the tail section and you should ensure the scale is

positioned on rigid mountings.

The position

should also be away from machines that might cause vibrations as this will

affect the scale readings. Extensive even horizontal stretches are the best but

with the right positioning of idlers even a slope can do. For convex belts the

best location should be 12 m to the retreat side and 6 m on the approach side.

For convex belts minimum distance from the tangent points of the curve is 12

meters. It is also important to avoid placing the scale too close to the feeder

because the material will not have loaded.

Minimize Variable Belt Tension

Over time, belts

tend to sag due to temperature variation and the load. Such variations in tension will affect the

scale and hence a gravity take-up is recommended. This helps to reduce the

impact of tension of the slack on the belt. The take-up, however should move

freely and consistently place tension on the belt. At the same time you should

not overload the belt because not only will this affect the scale but also the

belt.

Idlers Alignment

Idlers determine

how well your scale will function and they should be precisely positioned. Two

idlers should be aligned on both sides of the scale. For higher accuracy levels

you can use more than two idlers. To align precisely use a wire over the roller

edges and tighten until you are sure there is no slacking. Work on the rollers

until you are sure they are even. It is important to only use idlers of the

same size, shape, make and style for easy alignment. The idlers also need to be

scaled at equal distances.

Leverage Speed sensors

Speed is another

important determinant of the accuracy your conveyor belt scale gives. Sensors should be

attached to the tail pulley or alternatively the bend pulley shaft where the

connection cannot slip. Mounting of a speed sensor should also be on a solid

face pulley. If you use wheel driven speed sensors that are used with the return

strand of the belt place them close to a return idler. This guarantees a stable

drive surface to guarantee accuracy.

Optimize Your Wiring

Speed sensors

are susceptible to radio frequency interference and when wiring the unit ensure

you follow instructions to avoid inaccurate scale readings. Use shielded cable, grounded metal conduit

and terminal blocks throughout the circuit to avoid such interference.

Invaluable Maintenance Tips

The way you care

for your belt scale determines

its efficiency and life. The question

that comes to mind is where do you start? Well, here are some highlights:

General

maintenance: Your scale needs to be cleaned regularly and lubricated. You also

need to keep a lookout for any slack in tension and also alignment. The belt should

be trained to stay on course while extreme loading must be avoided. Belt

scrapping also helps you to get ideal readings.

Belt

calibration: Determinants in this crucial maintenance

procedure of conveyor belt include its condition, seasonal temperature

changes, prior maintenance, and expected accuracy. It is advisable to start

with a small calibration interval after installation as you learn how badly the

scale is deviating. You can later increase the calibration intervals if you

find a large deviation from the accuracy you desire. Speed tests, zero tests,

span tests must be carried out during calibration.

Weather factors:

Temperature shifts are the worst nightmare when dealing with scale maintenance.

You can avoid gravity tensioning device to mitigate effects of temperature

changes.

Your belt scale

is an invaluable part of your business. To enhance your scale’s efficiency

follow these tips and always remember they are there, lest you forget to

maintain them religiously.